3-D Printing Expands to School of Pharmacy

Last Updated on May 10, 2018 at 12:00 AM

Originally published May 14, 2018

By Laura L. Acosta

UTEP Communications

Albert Nava’s interest in pharmacy started in middle school when his grandfather suffered a bad reaction to an ingredient in a prescription medication he took.

Fortunately, the effects weren’t harmful long-term. But the experience showed Nava how important it is for pharmacists to ensure patients receive medications that are safe, effective and properly formulated to exclude problematic ingredients.

“I learned that a pharmacist is responsible for more than counting pills and putting them in a bottle,” recalled Nava, a pharmacy student at The University of Texas at El Paso. “A pharmacist should be aware of those types of problems. It opened my eyes that I can help people feel better but also save lives.”

While medications can be used to treat particular conditions, individuals may respond to the same drugs in different ways.

That is why Nava is excited about a new collaboration between UTEP’s School of Pharmacy and the College of Engineering that will introduce pharmacy students to additive manufacturing, or 3-D printing. The technology has the potential to enable future pharmacists to custom-print drugs tailored to specific patients.

The collaboration also is strengthening interdisciplinary research and education by engaging faculty and students from pharmacy and engineering in projects pertaining to 3-D printed food and drug delivery systems.

“We’re taking a compounding lab this semester, so we’re learning to create different dosage forms, whether it's creams, tablets or capsules,” Nava explained. “To be doing that in the lab and to hear about the possibilities of what we can do with a 3-D printer in our lab is just exciting.”

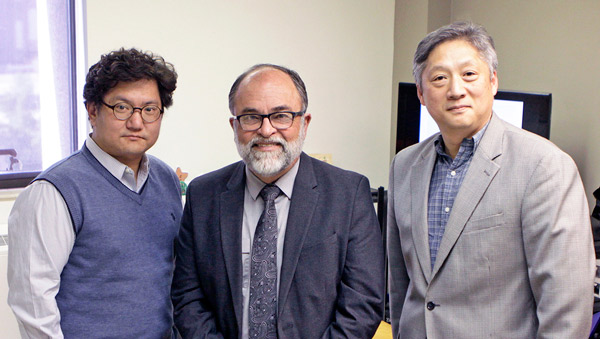

In January 2018, Jongwha Chang, Ph.D., assistant professor of pharmacy, and Namsoo Peter Kim, Ph.D., associate professor of metallurgical, materials and biomedical engineering (MMBME), established the Center for Advanced Food Printing and Pharmacy Training (CAFÉ-PPT) in the School of Pharmacy.

Researchers will use 3-D printing technology to create edible food products and design new drug delivery systems that control when and how much of a drug is delivered to the body. The CAFÉ-PPT also will engage pharmacy students in hands-on learning opportunities.

“The adaptation of novel 3-D printing techniques may one day make it possible for pharmacists to utilize this technology to produce personalized drug delivery systems and dosage forms,” said School of Pharmacy Dean José O. Rivera, Pharm.D. “Pharmacists will be able to print a tailored dose of a liquid suspension for a pediatric patient or develop food products for patients with diabetes, hypertension or high cholesterol to improve their conditions. Our collaboration with engineering will create opportunities for our pharmacy students to gain experience working with 3-D printing and potentially expand their scope of practice.”

New 3-D Printing Applications

In the CAFÉ-PPT, Jonghyun Lee, a graduate from the MMBME dual bachelor's degree program between UTEP and South Korea's Seokyeong University, is working with students from engineering’s Printing Nano Engineering (PNE) Lab to build 200 3-D printers. They are using technology Kim designed as part of a cooperative agreement with Seokyeong University.

Kim expanded the PNE program in 2016 with a grant he received from the National Research Council of Science and Technology. Since then, UTEP PNE researchers and students have been working with 3-D printing technology and biotechnology to 3-D print biomaterials.

Chang and Assistant Professor of Pharmacy Jwala Renukuntla, Ph.D., will use the PNE technology to print a microneedles-based nicotine patch. They will be working with Rina Koyani, an MMBME research fellow, on the fabrication of the non-invasive transdermal drug delivery device, which is made up of microscopic needles that painlessly penetrate the skin to deliver precise amounts of a nicotine.

“I believe a lot of our students are interested in research related to using 3-D printing,” said Chang, who plans to incorporate 3-D printing into the School of Pharmacy’s curriculum in the near future. “The study of drug delivery systems is an important part of the pharmacy program, and students who are interested will be able to take part in this innovative research.”

Personalized 3-D Printed Food

PNE students learned how to design and modify 3-D printers, including a food printer that can print high viscosity material, such as pizza dough, explained Diana Cho, a research assistant in the PNE lab and a graduate from the MMBME dual bachelor's degree program.

The CAFÉ-PPT will use the technology to conduct research on printing customized food for people with chronic diseases, such as diabetes, or for people with food allergies or food sensitivities.

“We have developed our own strategy and our own technology to 3-D print our own materials,” Cho said. “And we have invested so much time to make it applicable for everyday use like to 3-D print foods using healthy ingredients. This is very good because you can customize everything. For pharmacy, you can customize it to print medications in different flavors and sizes.”

Cho’s colleague Ji Hye Kim demonstrated how the printer uses a 1.66 millimeter needle to print the UTEP logo out of caramel on top of a cup of coffee.

“One of the things we can control is the exact amount of ingredients we use with this 3-D printer,” said Kim. The Journal of Food Engineering recently published a paper on 3-D printed food techniques written by Kim, MMBME research fellow Jae-Seok Eo, and Cho. “So for somebody who is diabetic or has a chronic disease, we can control how many grams of carbohydrates we inject into the food they eat.”

While the center’s 3-D food printing research is still in the preclinical stage, Chang hopes to one day collaborate with UTEP’s Department of Public Health Sciences on the nutritional value of meals.

“UTEP is trying to focus on interdisciplinary education, and this collaboration between pharmacy and engineering is a great example of that,” Chang said.

For more information about the School of Pharmacy click here. To learn more about Metallurgical, Materials and Biomedical Engineering at UTEP, click here.