Power Up: UTEP Expands Energy Research to Achieve Global Impact

Last Updated on December 07, 2020 at 10:00 AM

Originally published December 07, 2020

By Christina Rodriguez

UTEP Communications

Faculty members from The University of Texas at El Paso’s Department of Mechanical Engineering are on a mission to clear the air.

Their goal is to expand energy-related initiatives and position the University as a leader in renewable and clean energy technology research to advance opportunities for students and positively impact climate sustainability on a global scale.

A group of mechanical engineering faculty comprising several of the University’s engineering research centers are taking the lead on energy-related projects that provide unique solutions to some of the industry’s most pressing challenges. This includes using multiple energy sources to improve sustainability, reduce harmful emissions and foster affordable energy access.

“Increased reliance on renewables is significant,” said Jack Chessa, Ph.D., chair of the Department of Mechanical Engineering. “Renewable energy is a major job creator as well as a way to a better environment and energy independence in the future. It is a multifaceted effort to revamp this area, and we have several faculty members currently working on transformational renewable energy projects.”

UTEP’s W.M. Keck Center for 3D Innovation, Aerospace Center (also known as cSETR) and the Center for Advanced Materials Research (CMR) are critical in the work and research being done on renewable and clean energy at the University. Faculty from each center work synchronously to advance innovative energy-related research through projects funded by the U.S. Department of Energy (DOE) as well as other government agencies and industry leaders.

Many U.S. power generation systems still use fossil fuels such as gas, coal and other natural resources to produce electricity. Advanced sensors and controls can significantly increase the efficiency of these power plants and drastically reduce carbon dioxide emissions.

A team led by Ramana Chintalapalle, Ph.D., professor of mechanical engineering and CMR director, is working with the DOE to develop sensors and advanced materials systems that can be deployed in combustion systems to improve thermal efficiency. With funding from a new award from the DOE, Chintalapalle and his team also will focus on utilizing the quantum phenomena and atomic scale processing of materials for sensors and automation of energy systems.

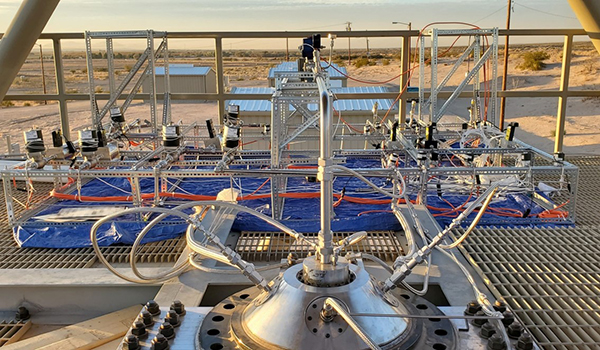

Faculty from the Keck Center and cSETR under the leadership of Yirong Lin, Ph.D., professor of mechanical engineering, have developed new cutting-edge concepts to design and produce components with structurally integrated sensors that can withstand high temperatures and other harsh environmental conditions to keep power plants running in a way that makes the air cleaner and reduces fuel consumption.

Lin’s work focuses on developing wireless senor technology for energy systems applications. His research includes the use of vibration energy harvesting — converting vibration energy to electrical energy to recharge the wireless sensors so they can continually monitor the power generation process.

cSETR researchers under the direction of Chessa and Joel Quintana, Ph.D., assistant research professor with mechanical engineering, also are working on next-generation combustor technology that burns fuel with oxygen to improve the emission of not only carbon dioxide but other pollutants such as nitrogen oxide and nitrous oxide. Rather than releasing in the environment, the combustion system allows carbon dioxide to be sequestrated underground to prevent its contribution to global warming.

Building a Strategy

In the future, the Keck Center and cSETR plan to evolve different areas of energy such as battery technologies for power generation and storage of solar or wind energy when there is an abundance to operate power grids with solar fuel when these natural sources are less accessible.

cSETR researchers plan to build on their approach of combining aerospace technology such as hydrogen storage technologies to address energy-related initiatives. The center is working on cryogenic storage processes to store rocket propellants on the lunar surface. The plan is to apply the same techniques for applications on Earth. Hydrogen fuel is a zero-emission fuel that can be used in fuel cells or gas turbines and internal combustion engines.

“The ability to take one technology from one area and put it in another is a unique way of doing things,” said Ahsan Choudhuri Ph.D., associate vice president for Aerospace Center and founding director of cSETR. “We are preparing to get more into battery and hydrogen storage to support the United States’ renewable and clean energy technology development push. We are the Sun City and believe we will play a big role in solar and renewable energy technology in the next five years.”

Also helping to expand solar energy initiatives, Chintalapalle recently received a multimillion-dollar grant to design and develop photocatalysis — a green technology that converts abundantly available photonic energy into useful chemical energy — based on oxide nanostructured materials, which will have implications in expanding solar and photovoltaic energy technologies.

Motivated by the rapidly evolving economy and commercial aspects, Chintalapalle and his team at CMR are heavily involved in materials design and development, enabling new directions in energy storage and conversion technologies. Projects focused on this central theme relate to lithium ion batteries, solar cells, electrical energy storage devices and supercapacitors.

“Developing cost-efficient materials and manufacturing methods is critical in alternate energy technology to meet the society’s current and emerging energy demands,” Chintalapalle said.

Chintalapalle and his team at the CMR also are working on energy technologies to develop thermal barrier coatings that play a key role in developing next generation gas turbines for power plants of the future.

Calvin M. Stewart, Ph.D., associate professor of mechanical engineering at UTEP, has been working with the DOE and the National Energy Technology Laboratory (NETL) to conduct research in several areas since he joined the University. Currently, he is working on a project with Los Alamos National Laboratory and Honeywell Federal Manufacturing and Technologies to develop new fuel cell technologies. His team is developing the earliest prototypes of additive manufactured fuel cells that are fully 3D printed, transforming the way fuel cells are designed.

Stewart also has been working with the DOE and the NETL on materials for power generation such as super alloys and structural materials that are used across the energy sector. During the past seven years, he and his team have been conducting materials testing, mathematical theory development, simulations and qualifications to ensure that materials have what it takes to withstand the harsh environment of power plants and the endurance to last for long periods of time.

“Typically, it is a competing demand of temperature, pressure or electrical resistance that affect how much efficiency and how much energy you can harvest out of an energy system, so fundamentally the materials research and development of better materials help us to build better and more efficient energy systems,” Stewart said. “The research we are doing with advanced manufacturing, additive manufacturing and accelerated qualification is going to have and has had a dramatic impact on the energy industry.”

Making an Impact for Students

Not only is the research of UTEP faculty transformative to the energy industry, but it also creates opportunities for students to make a lasting impact by joining the energy industry as part of the workforce.

UTEP recently partnered with the Nuclear Regulatory Commission to provide 10 students with $10,000 scholarships along with internship opportunities at national laboratories and top national energy industries.

UTEP faculty members including Lin, Stewart and Norman Love, Ph.D., professor of mechanical engineering and associate dean of the College of Engineering, were recipients of a three-year $3 million DOE grant for a UTEP-led collaborative initiative between five institutions called the Partnership for Research and Education Consortium in Ceramics and Polymers (PRE-CCAP).

The program includes collaborators from Florida International University (FIU) in Miami, Tennessee State University (TSU) in Nashville, as well as Los Alamos National Laboratory in Los Alamos, New Mexico, and Kansas City National Security Campus to establish a sustainable pipeline of highly trained, next-generation workers and a community of technical peers to support the core mission of the DOE’s National Nuclear Security Administration (NNSA) – to enhance national security through nuclear science applications.

“We are making an impact not only on research and education but on workforce development focused on energy,” Lin said. “Many UTEP students are now working in these DOE government agencies and they are making a difference.”

Through the PRE-CCAP program, UTEP students are given access to cutting edge research, tools, technologies, internships and co-ops along with professional development training.

“This program has helped catapult the growth in our energy research under cSETR to help connect us more deeply with the DOE, with industry and with national labs. It helped us do some really great things,” Stewart said.

UTEP also is working in collaboration with the Air Force Research Laboratory (AFRL) on materials and manufacturing projects and providing opportunities for graduate and undergraduate students to work along scientists and engineers at the AFRL in Dayton, Ohio. Ongoing research efforts are aimed at designing materials for high-power electronic devices for efficient use in the entire range of electromagnetic regions to utilize energy efficiently.

“Most of our students have been recently hired by the electronic engineering division of White Sands Missile Range, Lawrence Livermore National Laboratory Lab, Sandia National Laboratory and Pacific Northwest National Lab,” Chintalapalle said.

The innovative research of UTEP mechanical engineering faculty through the Keck Center, cSETR and CMR are positioning the University to leave a lasting footprint on the renewable and clean energy industry with global impact on sustainability and improving the environment while training the next generation of energy leaders.

“Working with cSETR, my goal is to help direct and expand this energy initiative,” Stewart said. “We have the keys to help build something bigger for the entire University, to build an energy research profile that spans multiple departments, crosses disciplines, solidifies our R1 status and makes a tremendous impact.”