Research

Research Thrust 1 — Intelligent Manufacturing

The research thrust focuses on integrating cutting-edge technologies such as artificial intelligence (AI), machine learning, and big data analytics into manufacturing processes. Our team aims to enhance automation, enable real-time monitoring, and implement closed-loop control systems. These advancements are designed to improve productivity, minimize human intervention, and create adaptive manufacturing systems capable of responding to changing demands, ultimately paving the way for smarter, more efficient manufacturing operations in the future industrial landscape.

Research Thrust 2 — Systems Modeling and Simulation (SMS)

SMS aims to create advanced virtual models that replicate and analyze any complex ecosystems. By integrating key modeling techniques such as Discrete Event Simulation (DES), Agent-Based Modeling (ABM), and Systems Dynamics (SD), this research enables the simulation of various manufacturing and healthcare scenarios. The focus is on performing multi-scenario experiments, conducting in-depth what-if analyses, and validating processes in a risk-free environment, ultimately providing insights for process optimization, resource allocation, and decision-making without real-world consequences. These models help improve system performance, predict potential risks, and support data-driven strategies in complex operations.

Research Thrust 3 — Augmented and Virtual Reality (AR/VR)

RIMES explores the integration of Augmented Reality (AR) and Virtual Reality (VR) technologies to enhance manufacturing processes, workforce training, and system design. AR enables real-time visualization of data, digital overlays for assembly guidance, and remote assistance, improving accuracy and efficiency on the shop floor. VR creates immersive, interactive environments for simulating production lines, testing layouts, and conducting risk-free training scenarios. Together, AR and VR provide powerful tools for prototyping, process optimization, and human–machine collaboration, accelerating innovation and reducing operational costs in modern manufacturing environments.

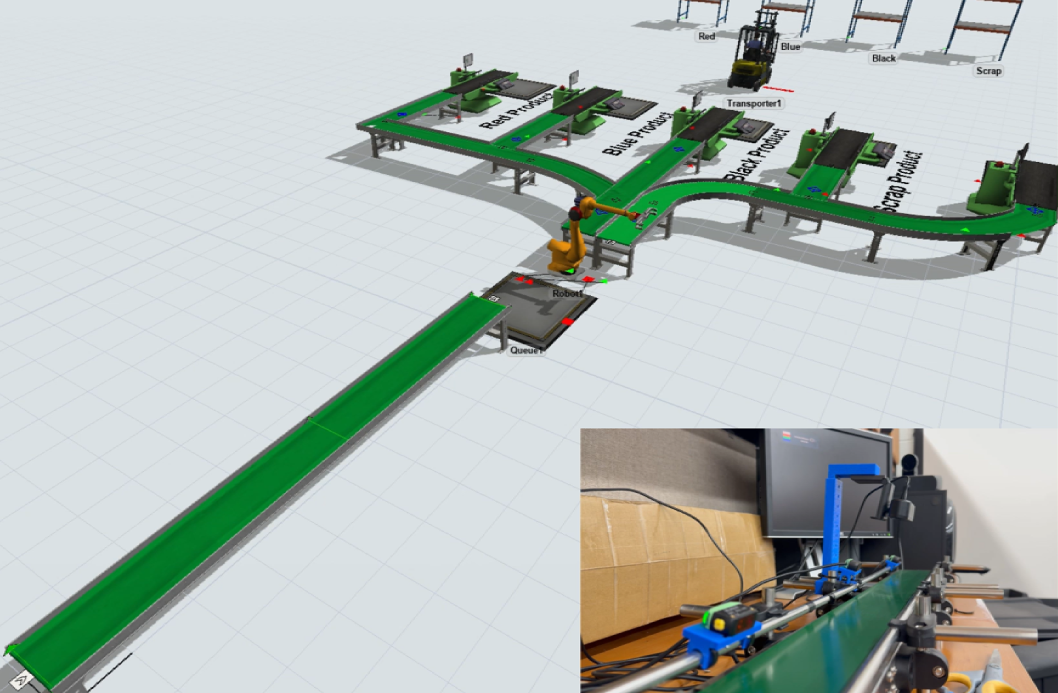

Research Thrust 4 — Digital Twins (DTS)

The DT research thrust, similar to the SMS, focuses on creating dynamic virtual models of physical systems. However, it uniquely integrates physics-based models with real-time data from sensors or vision systems embedded in the physical counterpart. Our team is developing multi-physics DTs that combine thermal, mechanical, and material behavior modeling, enhanced with AI/ML algorithms. This research bridges the gap between physical and digital environments, enabling more efficient, adaptive, and responsive manufacturing processes, improving decision-making, process optimization, and predictive maintenance.

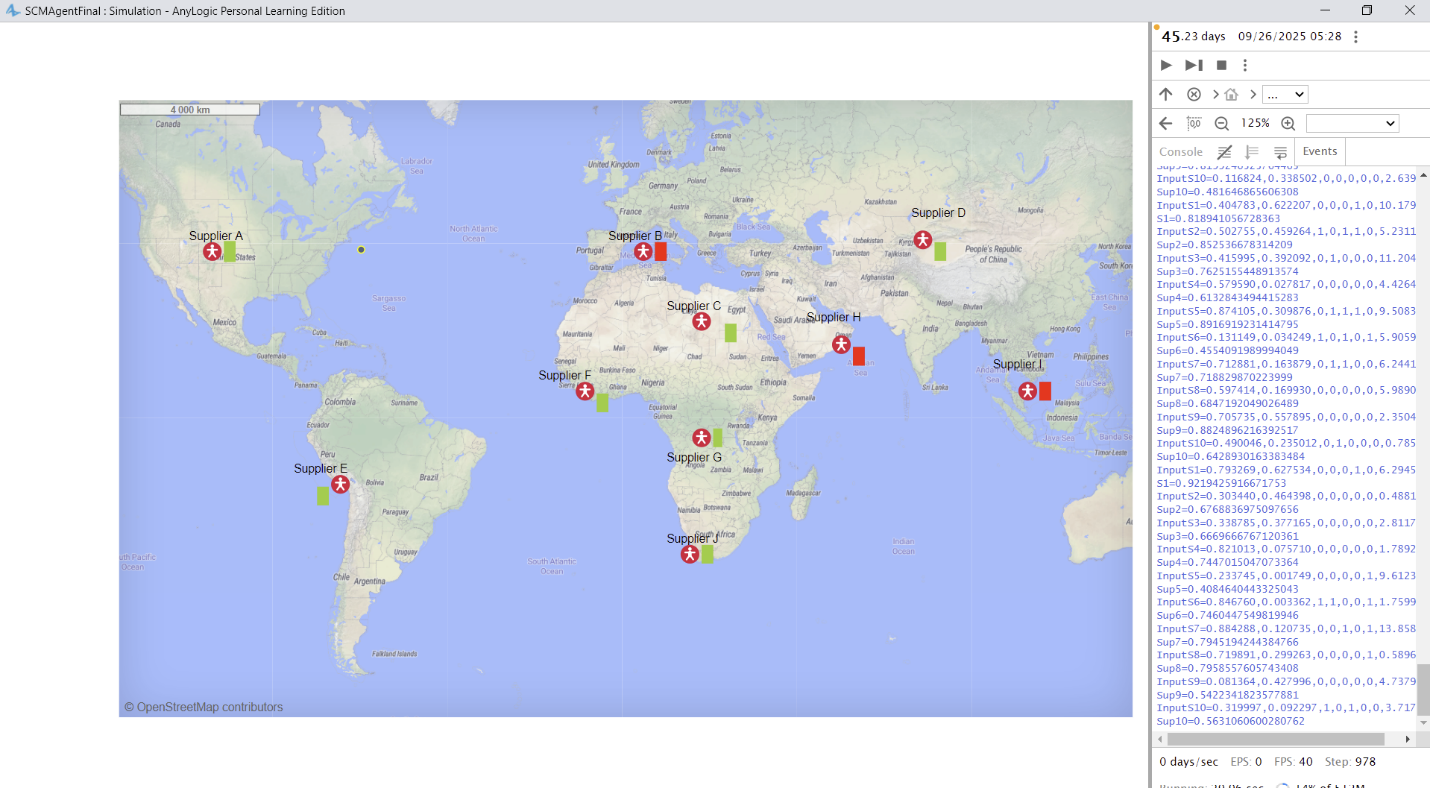

Research Thrust 5 — Intelligent Supply Chain

The Intelligent Supply Chain research aims to revolutionize supply chain operations by leveraging advanced technologies such as real-time GIS data, knowledge graphs, and automated data extraction. Our work optimizes decision-making, improves operational efficiency, and mitigates supply chain risks. By integrating these technologies, we enable real-time monitoring, predictive analytics, and seamless information flow, enhancing supply chain resilience, adaptability, and responsiveness, ultimately ensuring better performance and risk management in dynamic environments.

Research Thrust 6 — Industrial Data Analytics

This research thrust focuses on advancing biomedical image analysis techniques, such as CT, MRI, and X-ray imaging, to improve diagnostics and treatment planning. We integrate cutting-edge machine learning algorithms for tasks like image segmentation, anomaly detection, and predictive analytics. These innovations aim to enhance patient outcomes, optimize healthcare workflows, predict Length-of-Stay (LOS), and provide real-time, data-driven insights for personalized care, supporting informed medical decision-making and more efficient and smart healthcare delivery.