DRIVE AM

Driving Research, Innovation, and Value through Education in Additive Manufacturing

The vision of DRIVE AM is to produce superior, Additive Manufacturing

(AM, also known as 3D printing) educated military, domestic manufacturing workforce, and defense supply chain as well as provide a K-PhD STEM education pipeline and business creation ecosystem.

Our training sessions provide significant focus on the use of additive manufacturing and its applications. The content is well-balanced, consisting of hands-on excercises and lectures, utilizing state-of-the-art equiptment and software.

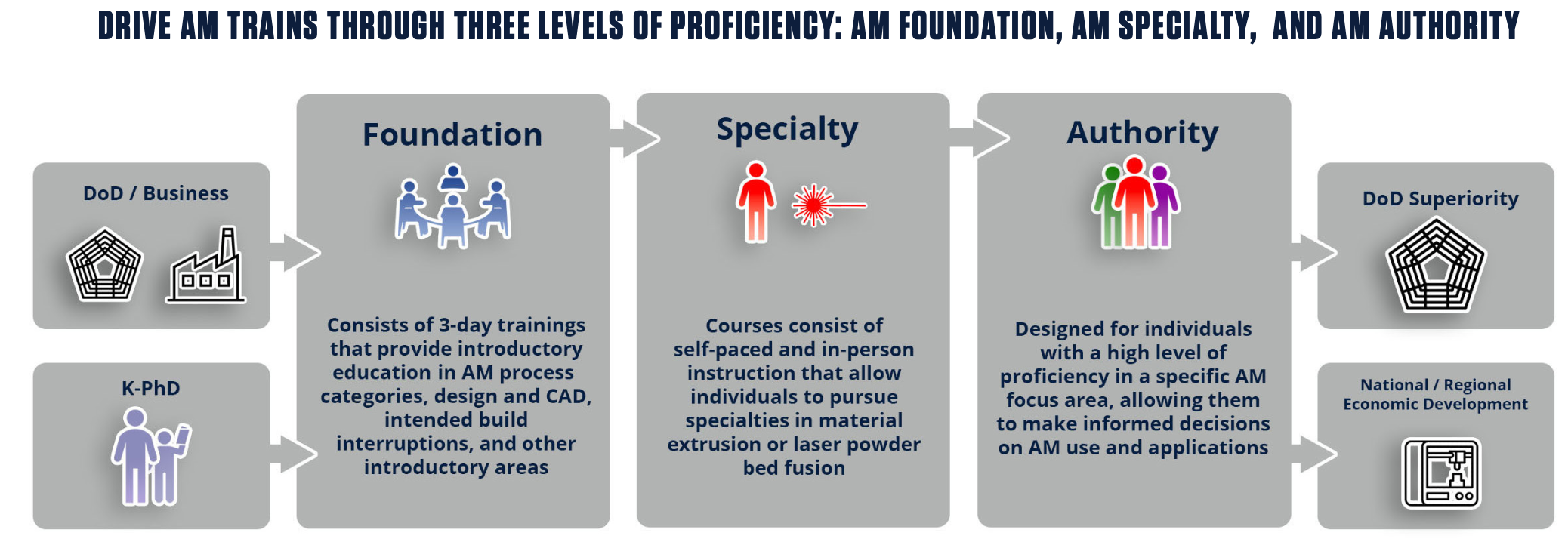

The DRIVE AM program trains at three levels of proficiency, each targeting soldiers, technicians, operators, engineers, DoD support personnel, personnel transitioning from the military, or veterans that are (1) in active roles in the military or DoD, or (2) in support of DoD through the defense manufacturing supply chain (including new AM-focused businesses created as a result of DRIVE AM and DRIVE 3D).

AM FOUNDATION

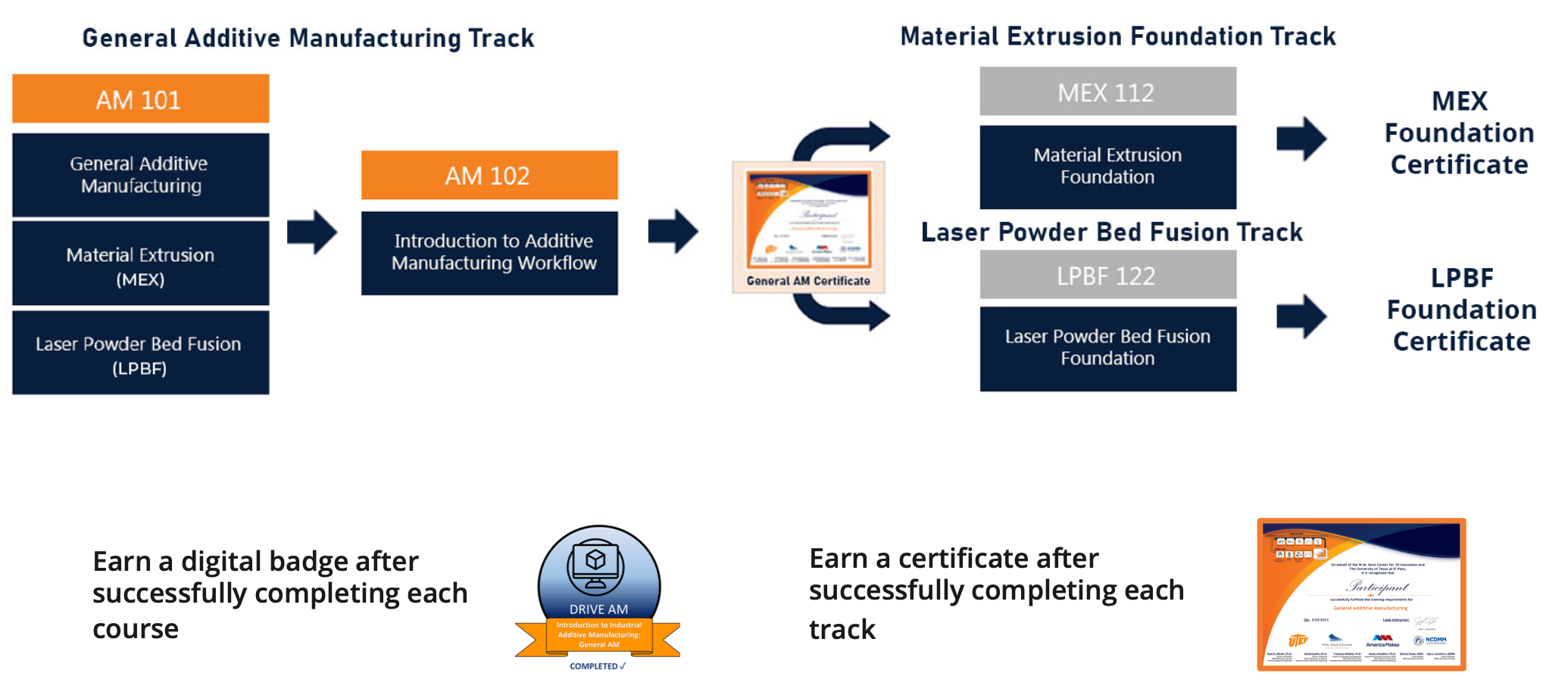

AM Foundation courses effectively introduce participants to the additive manufacturing workflow for desktop and industrial systems. These courses are currently available or all DoD personnel and DoD contractors. Engineering Foundation courses provide options for custom curriculum and are typically contracted separately. The learning objectives for each AM Foundation courses is described in further detail below.

Register for AM Foundation trainings HERE

Introduction to Industrial Additive Manufacturing (AM 101)

Duration: 3-Day Course

Location and Delivery: Virtual

Learning Objectives:

- Identify the seven process categories of Additive Manufacturing (AM)

- Learn the benefits and limitations of AM

- Have a general understanding of Stratasys F900

- Have a general understanding of EOS M290

Introduction to Additive Manufacturing Workflow (AM 102)

Duration: 3-Day Course

Location and Delivery: UTEP or AMIIC, Hands-on

Learning Objectives:

- Describe the limitations of Material Extrusion

- Design parts using Computer-Aided Design (CAD)

- Prepare parts for printing using slicing software

- Recommend solutions for common build errors

Material Extrusion Foundation (MEX 112)

Duration: 3-Day Course

Location and Delivery: UTEP, Hands-on

Learning Objectives:

- Understand fundamentals, process-parameters, capabilities and limitations of material extrusion

- Understand CAD modeling, slicer software, build file preparation and post processing techniques

- Apply the capabilities of design and print to create and test a capstone project

Laser Powder Bed Fusion Foundation (LPBF 122)

Duration: 3-Day Course

Location and Delivery: UTEP, Hands-on

Learning Objectives:

- Identify and explain the function of each of the six subsystems in every LPBF machine

- Understand the five makor factors of build success: build orientation, supports, gas flow, scan strategy, and re-coater functioning

- Prepare a file to print and experience LPBF

AM SPECIALTY

Building upon DRIVE AM Foundation, DRIVE AM Specialty allows individuals to develop more advanced proficiency in additive manufacturing. There is an existing comprehensive AM Specialty program offered exclusively to engineering students as a 15 credit-hour Graduate Certificate in 3D Engineering and Additive Manufacturing at UTEP. This program is specifically contributing to engineering technical workforce development needs by producing graduate engineers with advanced proficiency in additive manufacturing.

Register for AM Specialty trainings HERE

Additive Manufacturing in Practice (AM 201)

Duration: 1-Day Course

Location and Delivery: UTEP, Hands-on

Learning Objectives:

- Classify the basic 3D scanning technologies

- Design advanced features into parts using Computer-Aided Design (CAD)

- Prepare a solid model from point cloud data

- Prepare Finite Element Analysis using Solidworks