Asphalt Binder Lab

Pressure Aging Vessel: Condition procedure to simulate the hardening that asphalt binders undergo during service life.

Vacuum Degassing Oven: To remove the entrapped air during pressure aging.

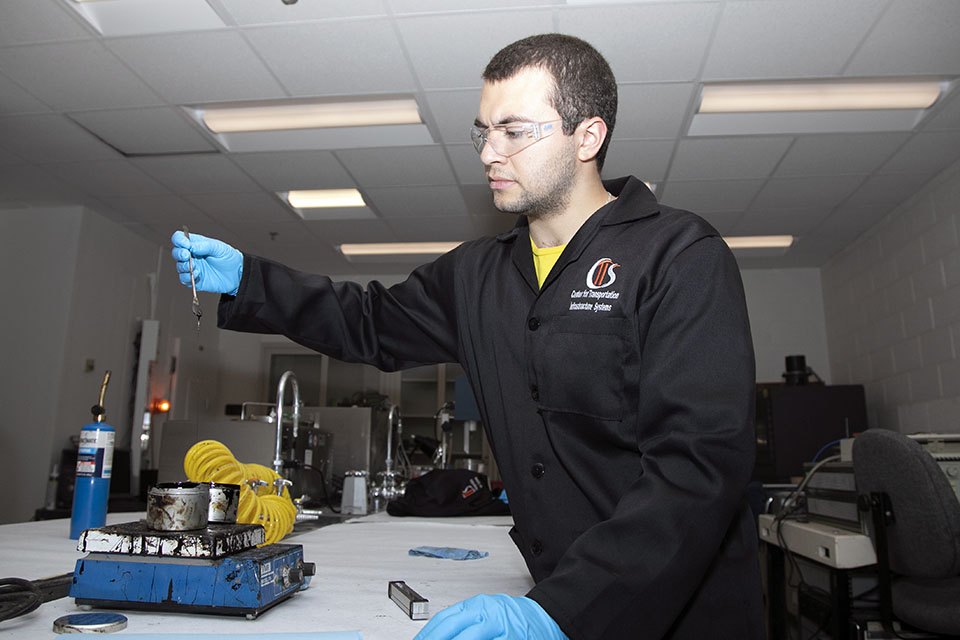

Rotational Viscometer: To identify the workable temperatures for production and compaction of HMA. Also to evaluate asphalt binder handling during delivery and plant operations.

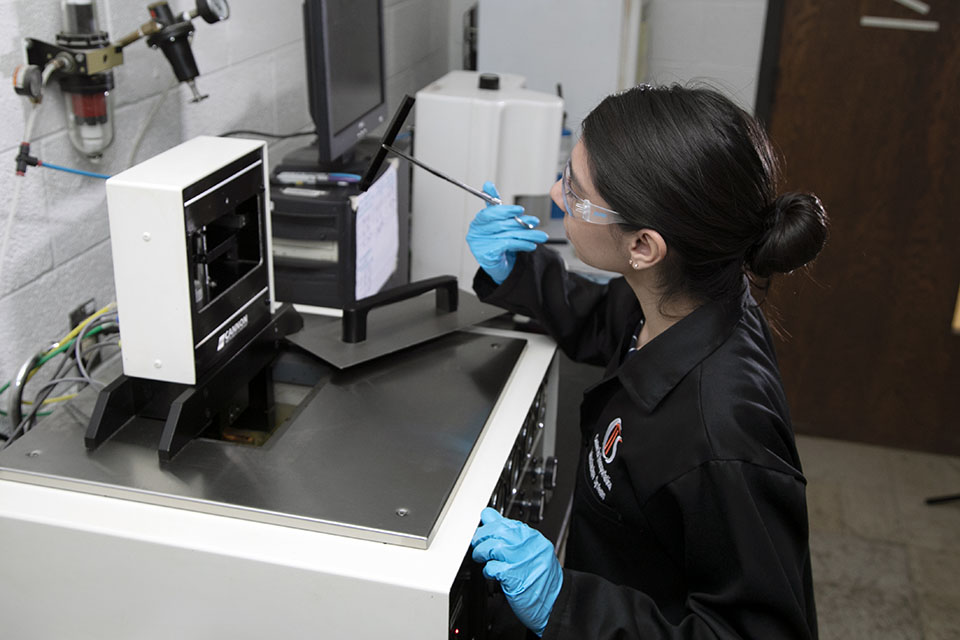

Dynamic Shear Rheometer: To characterize the viscoelastic properties of asphalt binders at intermediate and high service temperatures.

Bending Beam Rheometer: To determine the stiffness of asphalt binders at low temperatures.

Rotavapor: To recover asphalt binder from solvent extraction.

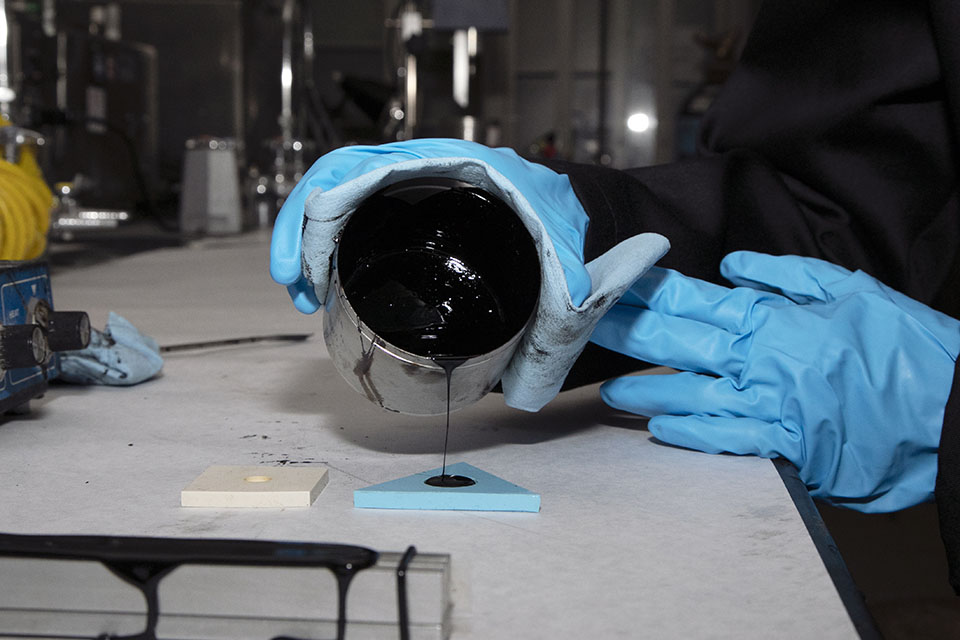

In the asphalt lab, all traditional and AASHTO binder testing equipment are available. Testing facilities for asphalt binder include: dynamic shear rheometer for characterization of asphalt binder at high and intermediate temperatures, bending beam rheometer to measure the low temperature properties of asphalt binder, rolling thin film oven and pressure aging vessel to simulate aging of asphalt binders, high speed centrifuge for asphalt extraction, Rotavapor for asphalt recovery, and rotational viscometers for viscosity measurements.