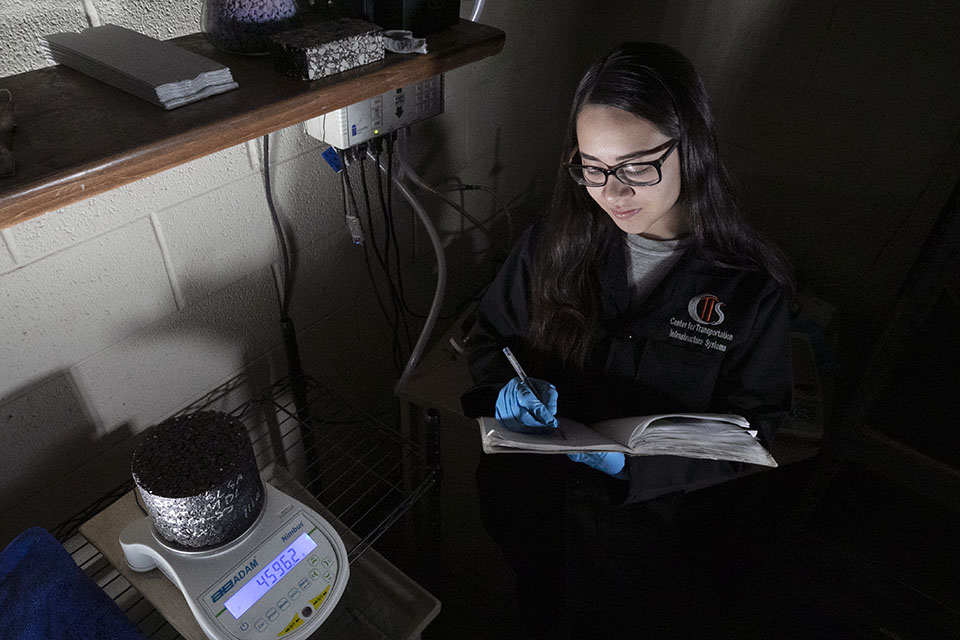

Hot Mix Asphalt Laboratory

Indirect Tensile Test: To determine the tensile strength of HMA..

Corelok: To determine the volumetric properties of HMA, specific gravity of aggregates.

Overlay Tester: To determine the susceptibility of HMA to fatigue or reflective cracking.

Dynamic Modulus Testing Setup: To determine the dynamic modulus of HMA at different frequencies and temperatures.

Moisture Induced Stress Tester: To determine the moisture susceptibility of HMA under the action of water and pressure at high temperature.

Repeated Load Permanent Deformation Testing Setup: To determine the permanent deformation properties of HMA at different frequencies and temperatures.

Flexural Beam Fatigue Testing Setup: To characterize the fatigue life of HMA at different frequencies and temperatures.

Asphalt mixture characterization facilities include: an MTS system placed in a walk-in temperature control room used for strength and modulus tests of hot mix, including all simple-performance tests and diameter resilient modulus, a Hamburg wheel tracking device, an Overlay Tester (OT), beam fatigue test device and Moisture Induced Stress Tester (MIST), Corelok for density measurements, Ignition oven for asphalt content measurements are also available.